POLYESTER FILTER BELT FOR SLUDGE AND SEWAGE SOLID CONTROL

Polyester mesh belting has open mesh surface allowing rapid drainage and outstanding cake release. It is used as sludge dewatering filter for vacuum press filter and multi-roll belt presses. Designed with steel joints or other connection styles.

Characteristics and Advantages of Drainage Mesh Fabric

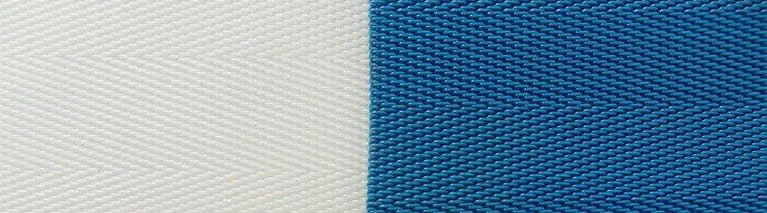

- Good water permeability

- Good air permeability

- Acid- resistance, alkali- resistance, temperature resistant

- Heat resistance under 180 degrees

- Waterproof polyester filter mesh for sludge dehydration with smooth surface mesh, high strength, excellent conduct electricity and saving energy;

Applications

Polyester synthetic filter mesh screen for dewatering is mainly used for sludge treatment in food processing industry and sewage treatment factories,such as paper making,printing and dying, washer wrinker fabric factory etc. Industries listed below:

- Filtration

- Sludge dewatering

- Industrial draining usage

- Food cleaning and processing

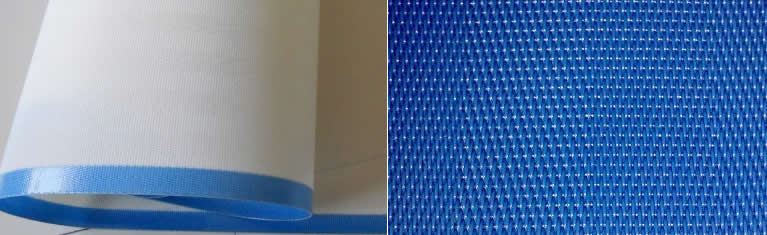

Sludge dewatering mesh belt used for wastewater treatment plants, illustrated as below:

Anti-static waterproof polyester fabric with good air and water permeation, while retaining the sludge

Hygenic Synthetic Filter Mesh with high draining capabilities used for Slurry Treatment in Fruit and Vegetable Juice Pressing. Supplied with either Polyurethane or PVC edges, suitable for the food processing industry. Easy to wash and clean.

Filtration Cloth Mesh for Vacuum Press Filter Belt in Solid and Liquid Seperation and Filtration

Waster Water Filter Mesh Netting Cloth Used as Press Belt, Dewatering Mesh for Paper Making Screen, as Drying and Forming Fabric

Materials and Specifications

Materials: 100% Polyester fiber.

Technical Specification List:

| Model | Wire diameter mm |

Density Root/10cm |

Air permeability m3/m2h |

Net weight g/㎡ |

Strength kg/cm |

Used in | ||

| Warp | Weft | Warp | Weft | |||||

| WNW14803 | 0.7 | 0.8 | 142 | 47-60 | 3900- 8500 | 1400 | 240 | Sludge, Squeeze juice |

| WNW16803 | 0.7 | 0.8 | 156 | 46-50 | 6000 | 1400 | 265 | Sludge, Squeeze juice |

| WNW16904 | 0.75 | 0.9 | 156 | 47 | 8000 | 1800 | 280 | Iron and steel industry sludge dewatering and Life sludge dewatering |

| WNW121054 | 0.9 | 1.05 | 120 | 42 | 8000 | 1650 | 340 | Iron and steel industry sludge dewatering |

| WNW22903 | 0.5 | 0.9 | 220 | 50-55 | 9000- 10000 | 1200 | 200 | Life sludge dewatering |

| WNW20703 | 0.5 | 0.7 | 200 | 70 | 10000 | 1000 | 185 | Life sludge dewatering and Chemical sludge dewatering |

| GW24504 | 0.5 | 0.5 | 240 | 130-140 | 8500- 10000 | 1180 | 220 | Paper dry network and Paper sludge dewatering |

| WNW08903 | 0.9 | 0.9 | 78 | 50 | 8500 | 1430 | 210 | Industrial sludge dewatering |

| WNW16704 | 0.7 | 0.7 | 160 | 90 | 12000 | 1350 | 265 | Building materials industries |

| WNW26908 | 0.5 | 0.9 | 26.4 | 69-75 | 5000- 5500 | 1364 | 240 | Viscosity of the large Sludge |

| CXW12 Mesh | 0.75 | 0.8 | 47 | 48 | 650 | 94 | Paper pulp washing | |

Other Belting Products You May be Interested:

Conveyor Belt for Fiberboard and Medium Density Board Processes

Press Belt for Horizontal and Vertical Belt Presses