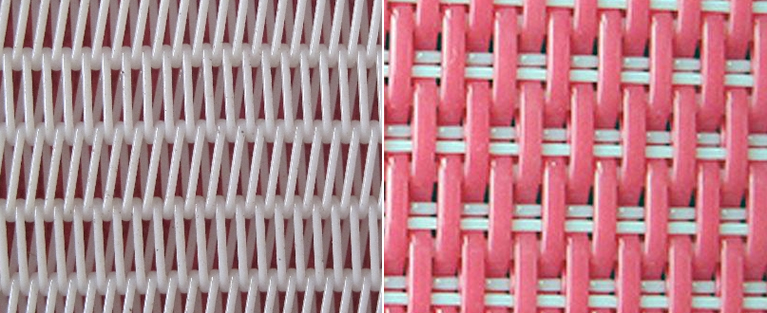

POLYESTER SPIRAL MESH FOR PAPER FORMING PROCESS, 4-shed, 5-shed, 7-shed, 8-shed and 16-shed weave, in single or multi layer fabrics.

Polyester forming mesh is made with 100% polyester monofilament fiber or nylon, woven in spiral and heddle inserting method. The tensile polyester fabrics form a tensile conveying belt in producing of paper, corrugated paper board, filtration and separation in environmental protection, pharmaceutical, mine, metallurgy, machinery, airspace and other fields. The synthetic polymer mesh netting enjoys a high degree of stability and long running life.

Procedure of Paper Producing and How is Polyester Mesh Used

Pulp diluting is first step for making papers and paperboards. The pulp is diluted, mixed, then conveyed through the forming fabric. Forming fabric is mostly thin fabric of polyester and polyamide monofilament which will dehydrate the slurry while retaining the wood fibers within. Hence, a kind of sheet is formed or molded. The fine polyester screen as conveyor belt used in this process, helps the sheet forming by offering effective drainage. It is called Forming Fabric. Normally, coarse mesh screen is used to manufacture heavy paper grades and corrugated paperboard boxes. Very fine mesh fabrics are selected for lightweight writing grade and printing grade papers manufacture.

Polyester forming fabric

can be supplied with different shed and layer styles, suitable for processing of different grade papers:

- 4-shed single layer mesh screen is suitable for making culture, printing and packing papers;

- 5-shed single layer mesh is suitable for making healthcare, culture and packing papers;

- 8-shed single layer fabric is suitable for making high basic weight corrugated and packing papers;

- 16-shed double and a half layer fabric is suitable for macking quality printing paper, tissue paper and surface pulp, inner pulp and base pulp of the board paper;

- Multi-shed three-layer fabric is suitable for making quality printing paper, tissue paper and cigatette paper.

Synthetic polyester forming fabrics used as paper making screen, can offer improved drainage and sheet consistency, higher production and longer life at a lower cost per ton of paper produced.

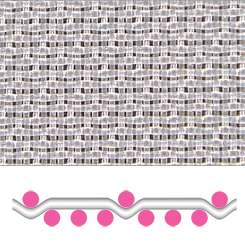

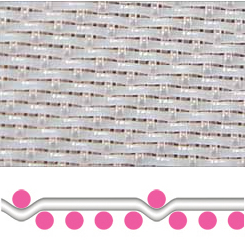

- Joint Types or Seams for Paper Making Screen:

Endless seam type, fold ring seam type, spiral ring seam or hook jointing.

Forming Fabric Screen For Advanced Printing Paper Manufacturing:

Slice Processing Mesh of 4 sheds for making surface pulp, inner pulp and base pulp of board paper

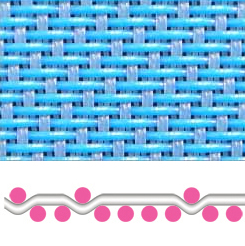

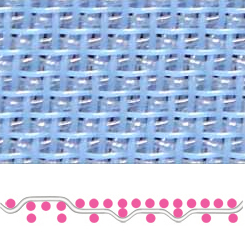

Sheds and Layer Styles of Paper Forming Screen:

|

|

|

| Four-Shed Single Layer Forming Screen, 0.68 elongation, 7500 air permeation | Five-Shed Single Layer Mesh Fabric, 0.60 elongation, 7000 air permeation | Eight-Shed Single Layer Polyester Fabric, 0.65 elongation rate, 9000 air permeation |

|

|

|

| Seven-Shed Double Layer Fabric | Eight-Shed Double and A Half Layer Fabric, 0.60 elongation, 4750 air permeation | Sixteen-Shed Polyamide Mesh in Double and A Half Layer Weave, 0.60% elongation, 8000 air permeation |

Feature

- Long service life, wear resistance

- High fatigue resistance, acid, weak alkali resistance

- Good forming uniformity

- Light weight, easy to transport, easy operation

Products Materials and Detail Technical Data

| Weaving Series and Types | Model of Fabric | Thread Diameter mm |

Density (pieces /cm) |

Strength (N/cm) |

Thick- ness mm |

Air Permeation m3/m2h |

Max. Elongation at 50N/cm |

|||

| Warp | Weft | Warp | Weft | Mesh Surface | Inserting Place | |||||

| Four-Shed Single Layer Forming Screen | 27254 | 0.20 | 0.25 | 30 | 22 | =600 | =400 | 0.49 | 8000 | 0.60% |

| 27254-1 | 0.20 | 0.25 | 30 | 23 | =600 | =400 | 0.495 | 7500 | 0.60% | |

| 27254-2 | 0.20 | 0.25 | 30 | 24 | =600 | =400 | 0.50 | 7000 | 0.60% | |

| 27274 | 0.20 | 0.27 | 30 | 21.5 | =600 | =400 | 0.51 | 7800 | 0.60% | |

| 27274-1 | 0.20 | 0.27 | 30 | 22.5 | =600 | =380 | 0.515 | 7300 | 0.60% | |

| 31204 | 0.18 | 0.20 | 35 | 28 | =600 | =380 | 0.43 | 7500 | 0.68% | |

| 31204-1 | 0.18 | 0.20 | 35 | 30 | =600 | =380 | 0.43 | 7000 | 0.68% | |

| 31204-2 | 0.18 | 0.20 | 35 | 30.5 | =600 | =380 | 0.43 | 6500 | 0.68% | |

| Five-Shed Single Layer Forming Screen | 28205 | 0.20 | 0.20 | 30 | 27.5 | =600 | =400 | 0.46 | 6800 | 0.60% |

| 30205 | 0.17 | 0.20 | 32 | 28.5 | =500 | =350 | 0.41 | 7100 | 0.60% | |

| 30175 | 0.17 | 0.17 | 32 | 29.5 | =500 | =350 | 0.39 | 6600 | 0.60% | |

| 31215 | 0.20 | 0.21 | 35 | 32 | =600 | =400 | 0.48 | 7000 | 0.60% | |

| Eight-Shed Single Layer Forming Screen | 25358 | 0.22 | 0.35 | 28 | 19.5 | =700 | =500 | 0.85 | 9000 | 0.65% |

| 25388 | 0.22 | 0.38 | 29.5 | 19 | =700 | =500 | 0.87 | 8500 | 0.65% | |

| 27358 | 0.22 | 0.35 | 29 | 20 | =700 | =500 | 0.85 | 8500 | 0.65% | |

| 27388 | 0.22 | 0.38 | 31.5 | 19 | =700 | =500 | 0.87 | 8000 | 0.65% | |

| Seven-Shed Single Layer Forming Screen | 50207 | 0.20 | 0.20/0.22 0.22(t66) |

54.7 | 36.6 | =800 | =600 | 0.71 | 5800 | 0.60% |

| 56177 | 0.17 | 0.17/0.20 0.20(t66) |

60 | 48 | =800 | =600 | 0.635 | 5200 | 0.60% | |

| 57177 | 0.17 | 0.17/0.22 0.22(t66) |

65.7 | 49.6 | =800 | =600 | 0.635 | 4550 | 0.60% | |

| 64177 | 0.15 | 0.17/0.17 0.17(t66) |

70 | 50 | =800 | =600 | 0.59 | 5200 | 0.60% | |

| Eight-Shed Double Layer Forming Screen | 56188 | 0.17 | 0.18/0.20 0.20(t66) |

61.3 | 51.2 | =850 | =600 | 0.65 | 5700 | 0.60% |

| 60188 | 0.18 | 0.19/0.20 0.20(t66) |

66 | 49 | =900 | =650 | 0.68 | 4750 | 0.60% | |

| 62188 | 0.15 | 0.16/0.19 0.19(t66) |

70.5 | 50.5 | =900 | =650 | 0.60 | 6200 | 0.60% | |

Eight-Shed and Sixteen-Shed Double and A Half Layer Screen Data

| Model of Fabric | Thread Diameter mm | Density/cm | Air Permeation m3/m2h |

||

| Warp | Weft (Up/Lower) | Warp | Weft | ||

| 2B3316 | 0.28 | 0.20,0.27/0.40,0.40 | 37~38 | 40~41 | 6000 |

| 2B3316-1 | 0.28 | 0.20,0.27/0.45,0.45 | 37~38 | 37~38 | 6000 |

| 2B3316-2 | 0.28 | 0.20,0.27/0.45,0.45 | 37~38 | 31~32 | 8000 |

| 2B5008 | 0.17 | 0.13,0.18/0.32,0.32 | 55~56 | 48~49 | 6500 |

| 2B5216 | 0.17 | 0.17,0.22/0.27,0.27 | 57.5~58.5 | 50~51 | 5300 |

| 2B5216-1 | 0.17 | 0.19,0.22/0.35,0.35 | 57.5~58.5 | 43.5~44.5 | 6200 |

| 2B5408 | 0.17 | 0.13,0.20/0.35,0.35 | 59~60 | 43~44 | 6300 |

| 2B5416 | 0.17 | 0.13,0.20/0.35,0.35 | 59.5~60.5 | 42~43 | 6000 |

| 2B5608 | 0.17 | 0.13,0.18/0.22,0.22 | 61~62 | 52~53 | 5700 |

| 2B5608-1 | 0.17 | 0.13,0.20/0.25,0.25 | 60~61 | 54~55 | 5600 |

| 2B5608-2 | 0.17 | 0.13,0.20/0.32,0.32 | 60~61 | 48~49 | 6000 |

| 2B5608-3 | 0.17 | 0.13,0.20/0.35,0.35 | 60~61 | 47~48 | 5600 |

| 2B5608-4 | 0.17 | 0.13,0.20/0.32,0.32 | 61.5~62.5 | 55.5~56.5 | 6900 |

| 2B5608-5 | 0.18 | 0.13,0.18/0.22,0.22 | 62~63 | 53~54 | 6800 |

| 2B5608-6 | 0.18 | 0.13,0.20/0.25,0.25 | 61~62 | 61~62 | 5940 |

| 2B5608-7 | 0.15 | 0.13,0.18/0.25,0.25 | 62~63 | 53~54 | 6600 |

| 2B5608-8 | 0.15 | 0.13,0.18/0.32,0.32 | 61~62 | 56~57 | 6400 |

| 2B5608-9 | 0.17 | 0.13,0.18/0.35,0.35 | 61~62 | 51~52 | 6900 |

| 2B5608-10 | 0.17 | 0.13,0.22/0.35,0.35 | 61.5~62.5 | 48.5~49.5 | 5800 |

| 2B5808 | 0.17 | 0.13,0.18/0.22,0.22 | 63~64 | 53~54 | 6500 |

| 2B5808-1 | 0.17 | 0.13,0.20/0.25,0.25 | 63~64 | 54~55 | 5000 |

| 2B5808-2 | 0.17 | 0.13,0.20/0.25,0.25 | 63~64 | 51.5~52.5 | 5100 |

| 2B6208 | 0.17 | 0.13,0.18/0.20,0.20 | 68~69 | 56.5~57.5 | 5500 |

| 2B6208-1 | 0.17 | 0.13,0.18/0.20,0.20 | 68~69 | 54.5~55.5 | 6000 |

| 2B6208-2 | 0.17 | 0.13,0.18/0.23,0.23 | 63~64 | 51.5~52.5 | 5100 |

| 2B6216 | 0.17 | 0.13,0.18/0.23,0.23 | 68~69 | 61.5~62.5 | 5600 |

| 2B6216-1 | 0.17 | 0.13,0.20/0.25,0.25 | 68~69 | 64.5~65.5 | 6400 |

| 2B6216-2 | 0.17 | 0.13,0.18/0.25,0.25 | 68~69 | 51.5~52.5 | 5400 |

| 2B6216-3 | 0.17 | 0.13,0.20/0.35,0.35 | 68~69 | 52.5~53.5 | 5500 |

| 2B6216-4 | 0.17 | 0.13,0.20/0.35,0.35 | 68~69 | 49.5~50.5 | 8000 |

| 2B6216-5 | 0.17 | 0.13,0.20/0.35,0.35 | 68~69 | 46.5~47.5 | 7000 |

| 2B6408 | 0.17 | 0.12,0.18/0.20,0.20 | 70~71 | 57~58 | 6200 |

| 2B6408-1 | 0.17 | 0.12,0.18/0.20,0.20 | 70~71 | 65~66 | 6500 |