WELCOME

Hebei Polyester Mesh Co.,Ltd. established in 1996, is a company that combines research, design, production and sales in synthetic polyester mesh netting for press filter and dewatering facilities. Mainly monofilament and low elongation polyester ( or nylon ) mesh products. Polyester Mesh is a synthetic fiber fabric sometimes written as Dacron Mesh or Nylon Mesh. Polyester fabric enjoys alkali resistance, high tensile strength, rear resistance, chemical resistance, suitable for wet, moisture and high temperature heat work environments.

TYPICAL WEAVING AND USES OF POLYESTER MESHES

Weaving:

Plain Weave;

Spiral Loops Link Weave.

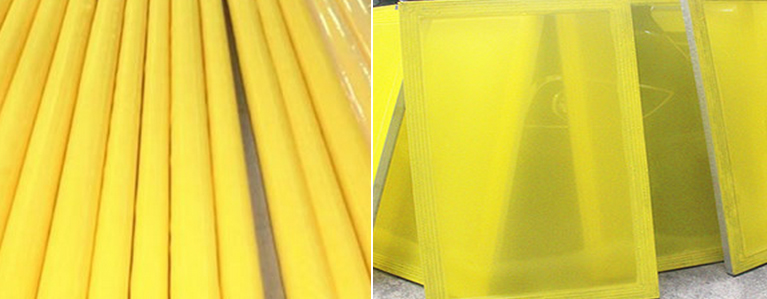

Plain Weave: Tensile Polyester Mesh Screen

We can supply 20mesh/ inch, 25 mesh, 30 mesh, 40 mesh, 50 mesh, 60 mesh to 420 mesh, with maximum roll width of 3750mm. The low elongation dacron mesh is replacing monofilament polyester mesh in screen printing with quick tension forming, high strength, stable tension and fast printing. Screen filter mesh made with material of PA and PET, polyester and nylon material.

Nylon polyester mesh is widely used in liquid and air filtering, mainly textile printing and dyeing, printing plate, electronic printing, ceramics, glass printing and other industries. Supplied in two forms of processing: needlefelt or woven mesh fabric.

We offer 20~1200 micron filter mesh in polyester and nylon material.

Application:

Plain woven synthetic mesh is mainly used as filter media in printing screen, bolting cloth, flour milling, sifting cloth.

Featured Products of Plain Weave Fabric: High Tensile Polyester Wire Netting of Monofilament Yarn Used as Stretchable Filter Screen in Silk Printing

100% Monofilament Polyester Wire Woven Mesh Fabric designed for auto-machine printing and manual printing. The tensile mesh has high strength, low elongation, good tension stability, suitable for stretching machine and repeated printing operations.

Color: White and yellow

Polyester filter mesh: 18mesh to 420mesh.

Screen Printing Mesh Accessories: Aluminum frames have smooth surface and stretching property to insure optimal tension.

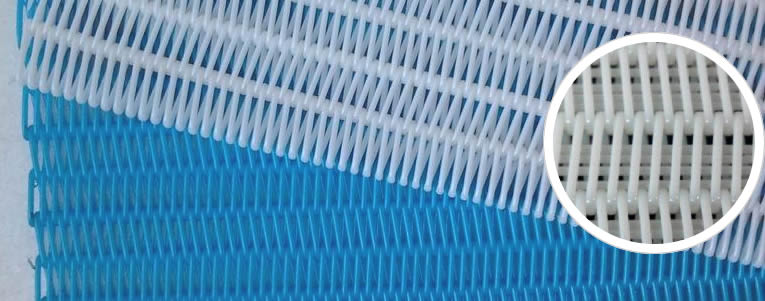

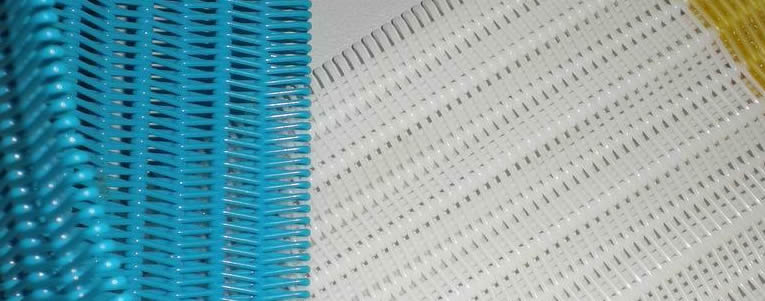

Spiral Link Weave: Mesh Belt, Supplied with or without Filled Wire

Spiral mesh is made with round or flat wire in the form of edge less, loop link, with filling wire or non filling. Weft wire and warp wire can be made with varies combination forms. Jointing can be insert, slot, frame, ring, spiral circle or stainless steel clips or fasteners.

Application

Used as process belt for various solid and liquid seperation filtration systems: Sewage treatment of municipal sewage, factoies slurry, pressing and dewatering of mill paper pulps, fruit juice pressing, power plant, mine and coal dehydration.

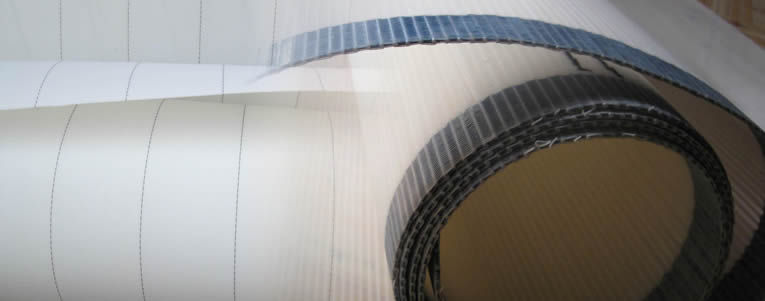

Featured Spiral Mesh: Filter Belt for Paper and Board Processing: Conveyor Belt, Press Belt, Dewatering Media Materials

Polyester Mesh enjoys better corrosion resistance and wear resistance over traditional brass and copper paper machine clothing. Since 1983, polyester screen began to be used in paper making industry in China. 1984, first full set of polyester mesh production line was imported from abroad to China. Now, we can produce single layer and multi layer forming fabrics woven with single, double, three or more sheds. Polyester filter belts are used as conveyor belts, or screen belts applied to various paper machine speed and roll and long nip press sections.

We offer the following spiral mesh paper mills fabrics:

Used as linear screen cloth;

Paper making molds mesh;

Papermaking screen drying fabric;

Forming fabric;

Pressing filter

mesh;

Pulp dewatering mesh.

Fabrics for Press Section: The sheet is carried through the presses by the polyester conveyor mesh fabric, at the same time, water is squeezed out and into the fabric. In this process, thhe paper surface finish is further influenced by the press fabric design. Using of monofilament mesh will improve or lower the water content of the wet web, thereby reducing the load on the dryer section. Our laminated and seamed press fabric offer superior performance in paper and board manufacturing.

Besides paper clothing, press fabric belt is also used for

fruit juice, fertilizers, wood-processing paper making, flue & gas; mining of coal and others.

Conveyor and Screen Belts for forming, dewatering and conveyor of the paper sheet through a paper machine.

The fabrics are either used as press draining meshes or as circulating pressing belts. A sheet of paper is created in the forming section as the slurry mixture flows evenly across the belt of the forming fabric. The fabric acts as a conveyor belt and a dewatering belt. As the belt moves, water drains through it, while the paper sheet of fibers and fillers form on the top of the fabric.

Our forming fabrics can be made with single or multilayer to match any standard paper machines in the world.

This dewatering fabric is also used as

chip mats in the wood-based materials industry, as caul screens in multi-stage presses, dewatering of sludge or fruit juice in double screen presses, hygiene and sludge treatment.

Dryer Fabrics hold the paper sheet in close contact with the heating cylinder, to ensure the remaining waters are removed through heat evaporation.

Want to learn more and all the products we offer, go deep inside.