POLYESTER DRYER FABRIC DRAINING SCREEN for Paper Pulp Drying Process

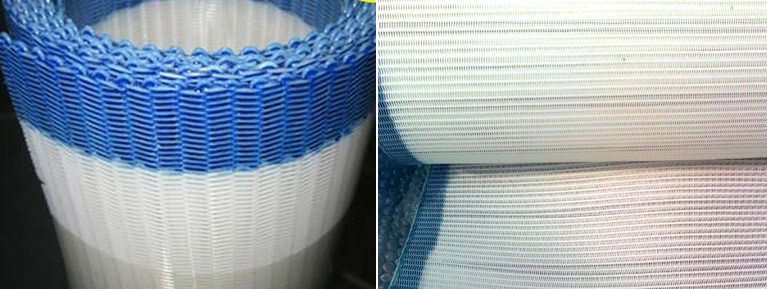

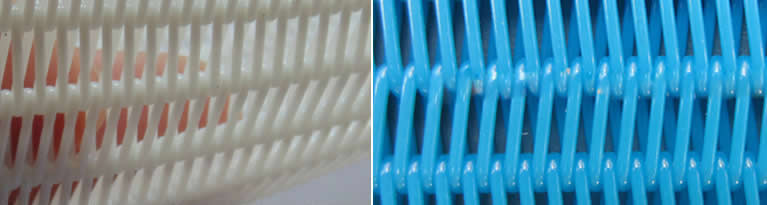

Plain spiral weave dryer mesh clothing is a process filter belt used for drying section in paper processing as well as other drying applications. According to the polyester fiber used, the dryer fabric can be made of two wire types: flat wire or round wire. The primary function of a dryer fabric as process belt in paper making, is to keep the sheet in contact with the dryer cylinders. Polyester dryer screen is heat-set at exacting temperature and tension to give maximum operation stability to ensure maximum heat transfer from the cylinder to the sheet.

24503/22503 Drying Screen designed for multi-cylinder paper machine clothing, for the first three groups of heating dryer cylinders, in production of maximum 70 grams paper and under.

24504/22504/20654/4106 Drying Screen is designed for multi-cylinder paper machine clothing with a higher air permeability. Generally used in the latter part of the dryer paper machine, for the production of papers with more than 70 grams unit weight.

4106-2 / 18688/16904 Model Drying Screen Fabric woven with flat wire, is generally used for multi-cylinder paper making machine, in the first three groups of paper dryer cylinder, for production of high-grade papers.

Application

Polyester ( Dacron) Dryer Fabric Used as Base Conveyor Belt for Drying Materials in Paper Making, Chemical, Sewage Treatment, Non Wovens and Foodstuff

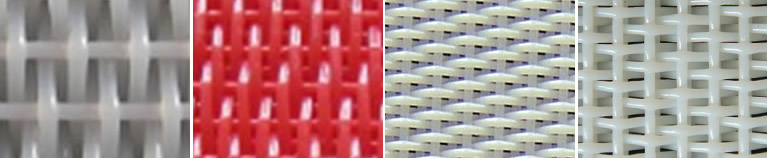

The synthetic dacron drying cloth enjoys good mechanical strength and high temperature resistance. The fabrics perform stably and consistantly well in a very hot and wet environment, can be used in filter process of many materials: powders, granulates and pastes, slurry, sludge, paper pulp sheet, woods and etc. Excellent resistance to chemical influences enables polyester mesh ideal conveyor belt for chemical industries.

Process of Paper Making and How Polyester Mesh is Used as Dryer Fabric

Dryer Fabric is used for Sheet Heating in paper making processes. At the drying part, the forming sheet is to be heated by steam-heated cylinders. The dryer mesh is used as press filter belt to ensure the maximum heat transfer from the cylinders to the sheet and minimum centrifugal force caused by the high machine speed. We use synthetic yarns of shrink-resistance, wear resistance, acid and alkali-resistance, weave in spiral pattern to form a smooth surface. The mesh fabric enjoys high dimensional and diagonal stability and good air permeability to ensure a smooth paper surface is produced.

Features:

Low permeability, smooth surface fabrics with very high contact area;

Very high contact area for improved drying;

Smooth surface for improved sheet quality;

Heat-resistance, high temperature resistance(180 degree);

Shrink-resistant,wear resistance, acid and alkali-resistant;

High dimensional and diagonal stability,good air ventilation.

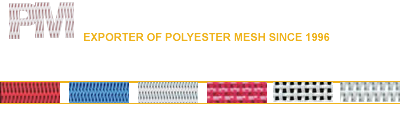

Loop Polyester Spiral Dryer Fabric for solid/liquid separation, as well as sludge dewatering for vacuum and multi-roll belt presses.

Polyester Dryer Screen Advantages

Flat surface;

Good air permeability

Stable property against heat and moisture

Low thermal shrinking, less elongation at heat

Resistant to most acids and organic solvents Safe for food processing.

Structure Types

Polyester paper making screen mesh can be divided into three sheds and four sheds according to weaving patterns and it can be divided into one and half mesh, double layer mesh and flat dryer mesh according to varieties.

Seam and connecting: Inserting type, slotting type, slotting ring and spiral ring connecting types.

conveyor or process Polyester belts in drying processes of copier and computer printer papers

Shrink Resistant Polyester Mesh Belt Suitable for machine speed under m600/s paper drying and printed textile drying.

Spiral Structure Mesh Dryer Fabric is suitable for high-pressure filter, widely used in all kinds of industries, such as printing and drying, food, salt industry, pharmacy, environment protection, coal mine, process, hides, shoe-making, clothing, ceramics, etc.

Ployester Spiral Dryer Mesh Fabric for Paper Making Screen Clothing:

Material: high quality Polyester monofilament in 100% PET.

Weave: spiral with or without stuffer yarns

Density: Different as to different specifications.

Loops: Small loop, medium loop, large loop, super loop.

Seam type: Spiral ring joint (spiral link), spiral open ended, stainless steel clipper, etc. Uses and Features: Polyester spiral mesh screen is mainly used in the dryness part of paper-making machines, drying process of printing and dyeing and other industrials.

Filter Press Fabric for Paper Machine Clothing in Paper Pulp Washing and Drying:

This kind of polyester belt can reduce the material loss from the mesh opening, used in sludge desiccation, paper pulp washing, coal washing, chemicals, dehydration of wine bran, vinegar bran dehydration and other industries. It is better in the high ventilation part of the drying part of paper-making machine.

Loop Types of Press Filter Mesh:

| Type | Specification of single loop(mm) | Monofilament Dia.(mm) | Strength (N/cm) | Thrickness (mm) | Weight (m2kg) | Air permeation m3/m2h | |

| spiral loop | Threading | ||||||

| Super loop | 4.8 x 10 | 0.9 | 1.1 | 2300 | 3.03 | 1.64 | 21000 |

| Large loop | 3.8 x 7.0 | 0.68 | 0.9 | 2000 | 2.45 | 1.40 | 18000 |

| Medium loop | 3.5 x 6.0 | 0.68 | 0.9 | 2000 | 2.45 | 1.31 | 16000 |

| Small loop | 3.2 x 5.2 | 0.5 | 0.8 | 1800 | 1.87 | 0.97 | 15000 |

Paper mahine dacron conveyor belt with smooth,seamless filter or conveying surface.

Materials and Specifications: Technical Specifications of Polyester Mesh for Industrial Draining and Drying

According to the weaving, polyester dryer fabric can be divided into 3-shed, 4-shed. According to the category, it can be divided into one and a half layer, double layer and rectangular wire fabric.

| Weaving Series and Types | Model of Fabric | Wire / Thread Diameter mm | Density (pieces/cm) | Tensile Strength (N/cm) | Weight kg/m2 | Thick-ness mm |

Air Perme- ation m3/m2h |

||||

| Warp | Weft | Warp | Weft | Mesh Surf-ace | Inser-ting Place | Spiral Conne-cting Ring |

|||||

| Three-Shed Series | 22503 | 0.50 | 0.50 | 24 | 12 | 2000 | 1400 | 900 | 1.06 | 1.9 | 8000 |

| 22453 | 0.45 | 0.45 | 24 | 13 | 2000 | 1400 | 900 | 0.99 | 1.7 | 8500 | |

| 24503 | 0.50 | 0.50 | 25 | 12 | 2000 | 1400 | 900 | 1.10 | 1.9 | 7000 | |

| 24453 | 0.45 | 0.45 | 25 | 13 | 2000 | 1400 | 900 | 1.02 | 1.8 | 6700 | |

| Four-Shed Series | 20504 | 0.5 | 0.5 | 22 | 12 | 2000 | 1300 | 850 | 1.15 | 2.0 | 15000 |

| 22504 | 0.5 | 0.5 | 24 | 12 | 2000 | 1400 | 900 | 1.26 | 2.1 | 12000 | |

| 24504 | 0.5 | 0.5 | 26 | 12 | 2100 | 1500 | 950 | 1.3 | 2.1 | 11000 | |

| 18504 | 0.5 | 0.5 | 20 | 11 | 1800 | 1200 | 800 | 0.85 | 2.0 | 8000 | |

| Round Thread Screen | 4106 | 0.5 | 0.70 | 22.8 | 12.4 | 2200 | 1500 | 900 | 1.3 | 1.75 | 6800 |

| 0.30 | |||||||||||

| Flat Thread Screen | 4106-1 | 0.58 | 0.35 | 21 | 15 | 2000 | 1400 | 800 | 1.2 | 1.50 | 2500 |

| 0.37 | 0.68 | ||||||||||

| 4106-2 | 0.58 | 0.35 | 21 | 14 | 2000 | 1400 | 800 | 1.2 | 1.5 | 3000 | |

| 0.37 | 0.68 | ||||||||||

| 4106-3 | 0.58 | 0.35 | 21 | 13 | 2000 | 1400 | 800 | 1.2 | 1.5 | 4000 | |

| 0.37 | 0.68 | ||||||||||

| 4106-4 | 0.58 | 0.35 | 21 | 13.5 | 2000 | 1400 | 800 | 1.2 | 1.48 | 3500 | |

| 0.37 | 0.68 | ||||||||||

Breaking Strength:

| LW4.0x7.0 | >2300-2800N/cm |

| LW3.8x6.8 | >2100N/cm |

| LW3.2x5.2 | >1800-2000N/cm |

Other screen products for paper making we supply:

Forming Fabric;

Spiral Mesh Screen;

Press Filter for Dewatering.